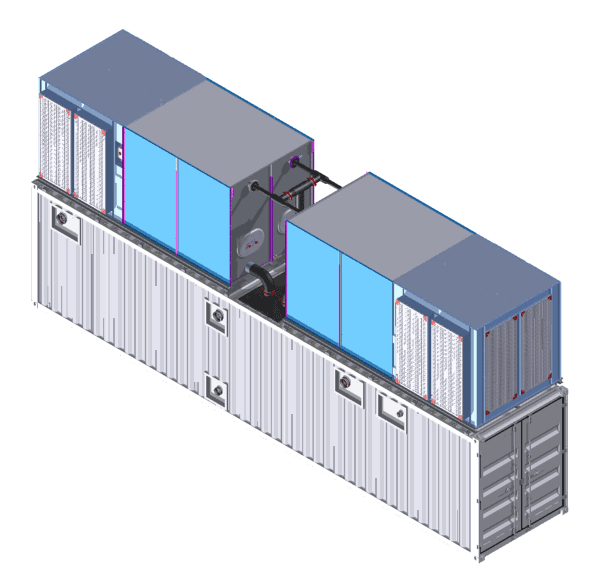

The modern container cooling systems are designed and manufactured to meet the needs of customers. Variable cooling capacities up to 2800 kW in a 40 ft container are possible. Energy efficiency is achieved through frequency-controlled pumps and cooling tower motors. Multiple circulation systems are possible for different consumers.

Modern controls allow monitoring of the operating states of the cooling system.

- 20 ft or 40 ft container

- Up to 2800 kW cooling capacity

- Integrated water tank with level control

- PLC controlled

- High quality stainless steel cooling towers

- Freshwater filter depending on need for fresh water (DN 15 – DN 200)

- Worldwide customer support

- Worldwide commissioning

- Simple assembly on jobsite

Optional:

- Cooling tower with intake air filter

- Cooling tower with silencers

- Integrated chiller

- Filling pump for fresh water

- Return flow safety for higher elevation consumers

- Interior heating in the container for frost protection

- Interior cooling for warm countries

- Different voltages / frequencies possible

- Frequency controlled consumer pumps

- Frequency-controlled cooling tower motors

Construction Container cooling systems of container facilities:

Frame:

Fully welded steel profiles with 8 x ISO corner fittings

Walls:

Steel profile 1,5 mm thick, profiled sheeting corrugated profile, primed

and painted

Floor:

With reinforced cross-beams, as well as partial reinforcement in the area

of the tanks

Inside floor:

4 + 1 mm corrugated steel profile welded tightly all around, primed and

painted

Doors:

Double doors standard front side with locking rods and circumferential

rubber gasket (with insulated container design door is also insulated),

option: 1 x steel personnel door with cyl.lock, door handles and

circumferential rubber gasket in integrated hinged door (with insulated

container design the door is also insulated)

Insulation:

Mineral wool insulation for sides, roof and all doors, clean edged with

interior paneling of smooth-walled galvanized sheet steel, joined and

riveted (floor is not insulated)

Cutouts:

Frame cutouts adapted for ventilation, fresh water supply, consumer feed

line/ return line, overflow, drain, container roof: cooling tower feed line/

return line

Roofplate:

Removable support structure statically supports with transverse beams,

to receive the cooling tower

Painting:

Exterior paint RAL colour as desired, incl. primer

Installation (tank) in steel or stainless steel: Design: hot- + cold zone

• Water level display

• Level control

• Pump protection against dry running

• freshwater supply