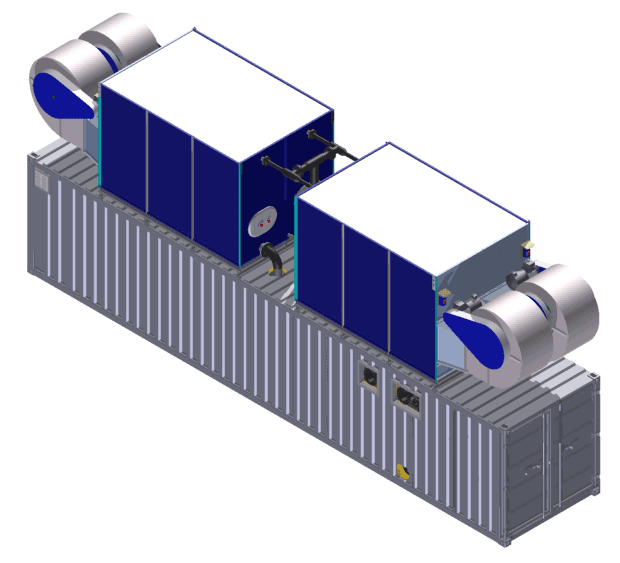

In cooling towers, the cold water heated in industrial or power plant processes is cooled.

Areas of application are e.g. plastic injection molding plants, foundries, welding shops, electroplating plants, breweries, bakeries.

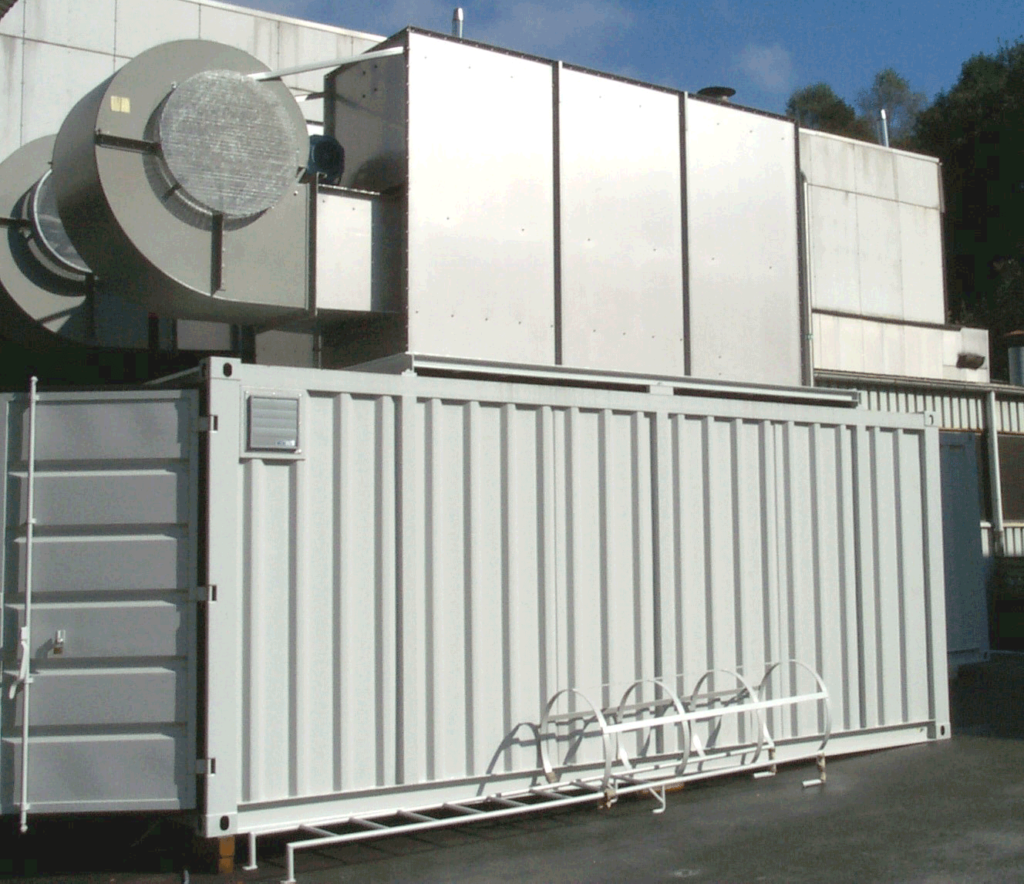

Housing and steel internal installations:

The housing of LISTER cooling towers with the water collection basin forms a fully assembled unit. It consists of a 2 mm thick sheet steel construction. The folded metal sheets, sealed with a permanently plastic material are bonded together by stainless steel screws. There is a sufficiently large sized inspection opening at the back of the cooling tower. Between the fan and cooling tower housing an exhaust vent is arranged to allow sufficient distance between the wet chamber and ventilation rotor

Material: Stainless steel, material no. 1.4301. The cooling towers thus offer an optimum cooling for the requirements of industry.

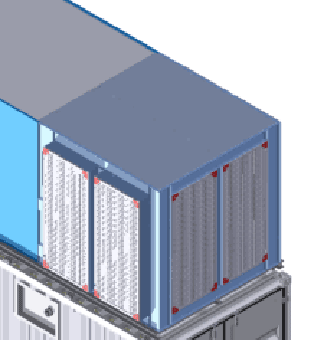

Filling material:

The filling body consists of plastic elements. These are characterised by a high exchange capacity, mechanical strength and relatively low pressure loss.

Droplet separator:

The droplet separator is made of plastic, with a high degree of separation.

Water distribution

The water is distributed through a system of pipes with PP hollow cone nozzles, which are largely insensitive to clogging. A uniform water distribution is ensured even at low inlet pressure. The individual nozzle tubes are easy to develop for maintenance by a plug connection.

Material: Stainless steel

Suction filter:

In the cooling tower in front of the discharge nozzle there is a screen box with a mesh size of about 5 mm, which prevents cavitation and is easily removable for cleaning.

Material: Stainless steel

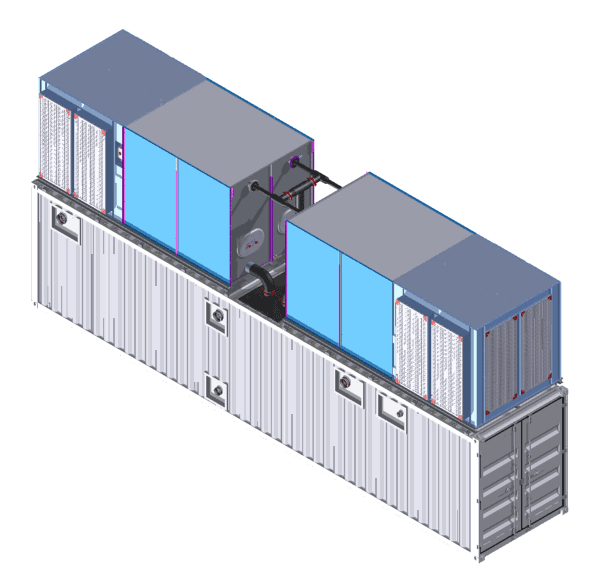

Fans:

As fans, double inlet, low pressure-high performance fans are used, which are characterised by high efficiency and low noise. The housing is made of galvanized steel sheet with additional corrosion protection with two-component painting. The drum rotors are balanced statically and dynamically. The fan shaft is designed in deep groove ball bearings, which are protected by labyrinth seals against dust and moisture. Relubrication via free lubrication lines, or in small series permanently lubricated bearings.

Drive:

The drive of centrifugal fans takes place via narrow V-belt by a standard three-phase AC motor. The belt tension can be easily adjusted by means of slide rails. The pulleys are made of wear-resistant cast steel and are secured by releasable clamping bushes. For reasons of operational security every fan is associated with a separate drive motor in multicellular units.